The CD17 was available for a number of years in a few variations, as detailed below:

- CD17. The base model, it uses a CDM12.1 laser mecanism, a SAA7372 servo and decoder, a SM5841 digital filter, a SAA7350 noise shaper, a TDA1547 DAC and an output stage based on NJM2114s and HDAM modules.

- CD17D. This player uses the same PCB as the CD17 but adds a digital input using a TDA1315 S/P DIF receiver, allowing use of the player as a DAC. The TDA1315 and its associated parts are not fitted on the regular CD17.

- CD17a / CD17 Mk2. An updated version of the CD17, it uses a VAM1201 laser mechanism and TDA1307 digital filter (in place of both the SM5841 and SAA7350). The TDA1307 was designed specifically for the TDA1547, but wasn't found in many players, most used an NPC digital filter and the SAA7350 as a noise shaper and upsampler. The VAM1201 also allows this player to player CD-RWs.

- CD17Da. Similar to the CD17D, this player shares the CD17a's PCB but adds a digital input using a TDA1315 S/P DIF receiver.

- CD17 Mk3. This player is significantly different to the others, using a different digital filter, DAC and output stage.

I've wanted a player using the TDA1547 for some time, but they're not particularly common and are usually fairly expensive. There are a huge variety of opinions on the sound of this DAC, the last DAC IC that Philips made for the high end market, but in my experience it is very competent.

This particular CD17 was inexpensive as it wasn't working properly, so I bought it to fix. It was in good physical condition, and in included the original packaging, manual and remote, but would not read a CD.

Unfortunately, unlike its predecessors, which all used swingarm laser mechanisms, the CD17 uses a cheaper CD12.1. These mechanisms have an inferior lifespan compared to the ones they replaced, so I suspected the laser had failed. The upside is that replacements for the CDM12.1 are easily available at low cost. I used a VAM1202, these are a suitable replacement for a CDM12.1.

At this point I removed the existing laser mechanism. The CD17 is very serviceable, only three screws and two connectors need to be removed to take out the loader, and you don't need to remove the drawer faceplate. Removing the laser mechanism from the loader is somewhat annoying, it is attached by four rubber grommets which need to be removed with care, as they are easily torn.

On examining the old mechanism I made a foolish decision. Time and time I have told people to change the whole laser mechanism and not to replace only the laser head. However, I looked at the old one, and the traverse seemed to be in reasonable condition, with no gear discolouration or apparent wear, so I ignored my own advice and bought a VAM1202 laser head.

On receiving the laser head I fitted it to the old traverse and fitted the mechanism back into the player. It powered up the player and it immediately read the disc (there is no setup when changing a laser with the SAA7372 based servo, the laser power is factory set on the laser head and the other adjustments are done automatically, a great feature). All seemed well, but shortly into a listening session it skipped slightly, and continued to do so occasionally throughout the disc, at an average interval of about 5 minutes. I removed the loader and carefully lubricated the transport again, but that didn't help.

I went back on eBay an purchased another VAM1202, complete with a traverse this time. I fitted the new complete laser mechanism, the skipping disappeared are the player now works well. The first laser head isn't a complete waste, as the laser head will serve as a useful spare in case the other fails prematurely, as they sometimes do.

At this point I gave the player a good listening test. I compared it directly against a Marantz CD16, the CD17's direct predecessor. The CD16 features a similar chipset, an SAA7310 decoder, SM5803 digital filter, SAA7350 noise shaper and two TDA1547 DACs (one per channel, differential output). Both CD players sound quite good, but the high frequency output of the CD17 was notably rougher and more metallic than the CD16.

After listening to it I had a think about what I wanted to change on the CD17. Though this player was built to a budget, it's still higher end than most of the players modified so far in this blog, and many items that I'd normally address just aren't as critical here. The passives are of generally high quality, and the player isn't as old as many I service, so there isn't the need to replace components due to age. Here are main things I think could be improved:

To connect the clock into the player I removed C111, C112, R108, R109 and X101, and fed signal to pin 21 of the SAA7372 (XIN). To do this I prepared a coaxial cable with an SMB connector at one end and separated and tinned ends at the other. I soldered the centre conductor to the now free crystal pad that connects to pin 21 of the SAA7372. I scraped the soldermask off a groundplane area next to that pad and soldered the shield to it. I then secured the joint between the cable and the PCB with glue.

I connected the DC supply to both sides of capacitor C854 (minding polarity). I installed a snap on ferrite on this cable. I then rechecked my wiring, powered up the player and ran through a function check. Job done.

A few things to watch when installing a clock:

I went back on eBay an purchased another VAM1202, complete with a traverse this time. I fitted the new complete laser mechanism, the skipping disappeared are the player now works well. The first laser head isn't a complete waste, as the laser head will serve as a useful spare in case the other fails prematurely, as they sometimes do.

At this point I gave the player a good listening test. I compared it directly against a Marantz CD16, the CD17's direct predecessor. The CD16 features a similar chipset, an SAA7310 decoder, SM5803 digital filter, SAA7350 noise shaper and two TDA1547 DACs (one per channel, differential output). Both CD players sound quite good, but the high frequency output of the CD17 was notably rougher and more metallic than the CD16.

After listening to it I had a think about what I wanted to change on the CD17. Though this player was built to a budget, it's still higher end than most of the players modified so far in this blog, and many items that I'd normally address just aren't as critical here. The passives are of generally high quality, and the player isn't as old as many I service, so there isn't the need to replace components due to age. Here are main things I think could be improved:

- Output stage: As standard, the CD17's output stage is actually quite good. The passives are of a very high standard, including mica capacitors and what appear to be thin metal film resistors. The opamps used, one NJM2114 per channel, aren't bad, but they could be improved with more modern types. I'm not going to change them right now, but it's something I may do at a later time.

- Final output: While the main part of the output stage is good, I'm not so enthusiastic about the final output. At the output of the 'HDAM' discrete buffer the signal passes through a bipolar electrolytic capacitor, followed by two transistor shunts to ground for muting, a ceramic capacitor to ground and then the outputs. None of this is ideal, and my plan is to replace this entire section with an auxiliary PCB. This PCB will include film coupling capacitors, muting relays (a reed relay per channel to shunt the signal to ground) and 100pF polypropylene film capacitors to ground. All in all the same functionality, but with less compromise.

- Low jitter clock: The clock system in this player is far below optimal. Initially I intend to replace the original clock source, but I also plan to change the clock distribution entirely at some point in the future.

Installing the Clock

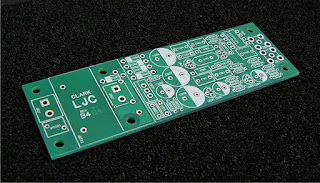

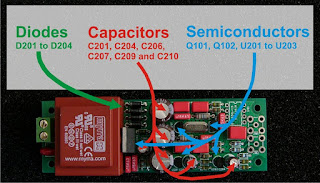

At this stage the only thing I've done is install the clock. I do plan on doing the two other things mentioned above, but at a later date. I also intend on this section being a loose guide for those who are installing the clocks they bought in the groupbuy.

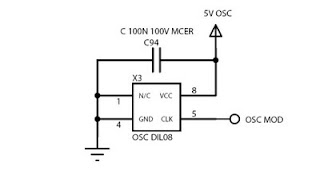

This first thing I did when installing the clock is familiarise myself with how the clock is generated and distributed in the player. This was complicated by the fact that this player's service manual is not available. The manual for the CD17 Mk2 can be downloaded, but it's quite different in some areas. I've drawn a diagram showing the clock scheme of the CD17 below (items in grey not fitted):

The SAA7372 decoder generates the clock, then buffers it to a 74HC257 multiplexer. This IC is redundant in models without a S/P DIF input, and is always set to the CD input. The output of this multiplexer is then fed to both the SM5841 and the SAA7350. The SAA7350 then divides the clock in two and feeds it to the TDA1547's two clock inputs. Most players aren't this complex.

Once I had determined where the player's original clock was located on the PCB I decided where to mount the clock PCB. I picked a place that was clear and as close to the clock as possible. It's important that the signal cable between the clock and the receiving IC is as short as possible. This cable shouldn't be more than 150mm. I drilled holes through the player's chassis and mounted the clock with two M3x6 machine screws and an M3x10 threaded hex spacer at each corner.

To connect the clock into the player I removed C111, C112, R108, R109 and X101, and fed signal to pin 21 of the SAA7372 (XIN). To do this I prepared a coaxial cable with an SMB connector at one end and separated and tinned ends at the other. I soldered the centre conductor to the now free crystal pad that connects to pin 21 of the SAA7372. I scraped the soldermask off a groundplane area next to that pad and soldered the shield to it. I then secured the joint between the cable and the PCB with glue.

I connected the DC supply to both sides of capacitor C854 (minding polarity). I installed a snap on ferrite on this cable. I then rechecked my wiring, powered up the player and ran through a function check. Job done.

A few things to watch when installing a clock:

- Identify the master clock. A CD player will often have more than one crystal, but in most cases only one has an impact on the sound quality. Make sure you're replacing the correct one.

- Check IC voltage tolerance. Many modern players use ICs that operate from 3.3V power supply rails. These ICs may not tolerate a 5V level signal, and you may need to build / buy a clock with a 3.3V level output.